Why Laminate in the First Place?

The laminate layer provides protection to the ink that is used to imprint a marker. Without laminating signs, they may last a couple of years and – toward the ends of their lives – do not look all that great any longer. With the laminate in place, the ink is protected from the elements as well as the damage that occurs from being touched.

The Right Equipment for the Job

There are plenty of laminating machines on the market. At the office supply store’s business counter, you are usually seeing the pouch laminator. You give the clerk a paper or poster to laminate; the worker selects the appropriate pouch size and then inserts the paper into the pouch. Once inserted into the machine, the heat activates the adhesive, which then adheres to the paper and protects its. To cut off extra laminate on the outside, be sure to leave a few millimeters of material to keep the watertight seal.

Hot or Cold? It Matters!

But there is more to laminators than just the technology that allows for small and large signs to be accommodated. In addition, there are the intricacies that involve hot, cold and dual laminate application. Knowing these differences is where we separate the experts from the one-trick-ponies in the business.

Hot laminator. This machine relies on heat to activate the adhesive. The use of an even heating method protects against bubbles and thick spots of material on the finished product. You can easily tell if the machine needs calibrating (or replacing) by unevenly heated adhesive.

Dual laminators. This is a must-have for the serious signage maker. Accommodating both the laminating needs of the vehicle graphics as well as those of the business clients in need of banners and posters, the machine offers the right type option.

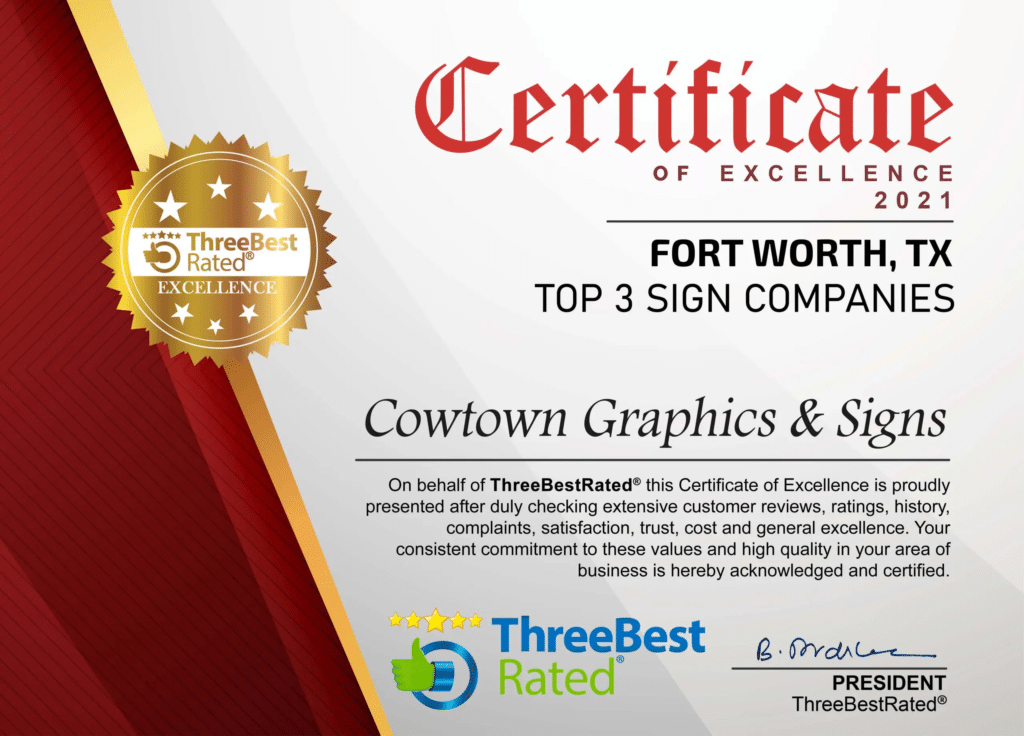

We hope that you enjoyed this little glimpse behind the scenes of the daily goings on in our industry. Please call the friendly professionals at Cowtown Graphics & Signs with additional questions.